Introducing Parabolic Paradomes innovative structure building system

Superior to Geodesics

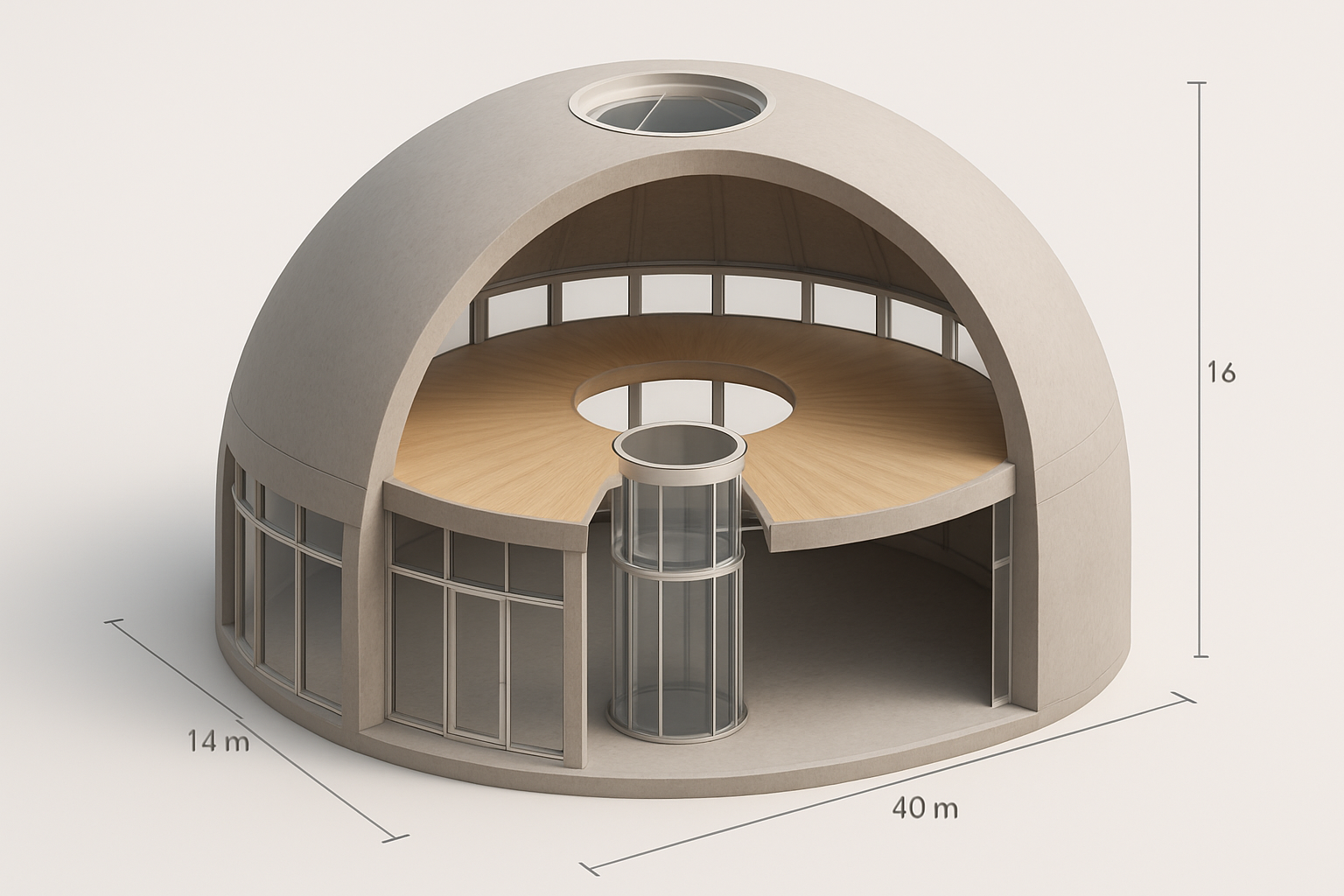

Parabolic Paradomes arrive at a prepared building site as a pre-manufactured kit consisting of large, relatively light, compound, curved panels. These panels are set in place with light machinery on level conventional compacted aggregate subgrades. and anchored with helical ground screws or conventional concrete piers, depending on existing soil bearing capacities. The Paradome panels can be quickly installed to form a radial structure that is subsequently belted together with our proprietary woven steel cable post-tensioned panel compression system. The Paradome panels' seams lock together to form a waterproof seal & have 90% fewer seams when compared to a geodesic building. Paradome structures deliver high strength, efficiency, and dramatically easier assembly compared to traditional geodesic domes. Discover why our modular approach leads the way in resilience and sustainability.

- Fewer Seams, Greater Strength

- Paradome panels interlock with minimal seams, significantly reducing structural weak points and enhancing durability. This design innovation means safer, longer-lasting shelters for your peace of mind.

- Modular & Efficient Assembly

- Large, modular panels make Paradomes quick to assemble with fewer parts, reducing labor and waste. Move from delivery to safe occupancy faster than with traditional dome structures.

- Disaster Resistant & Sustainable

- Paradomes utilize low-carbon, fireproof material composites for unmatched disaster resistance and environmental responsibility. Built to survive wildfires, storms, and a changing climate—without sacrificing comfort or design.

Advanced Construction for a Safer, Greener Future

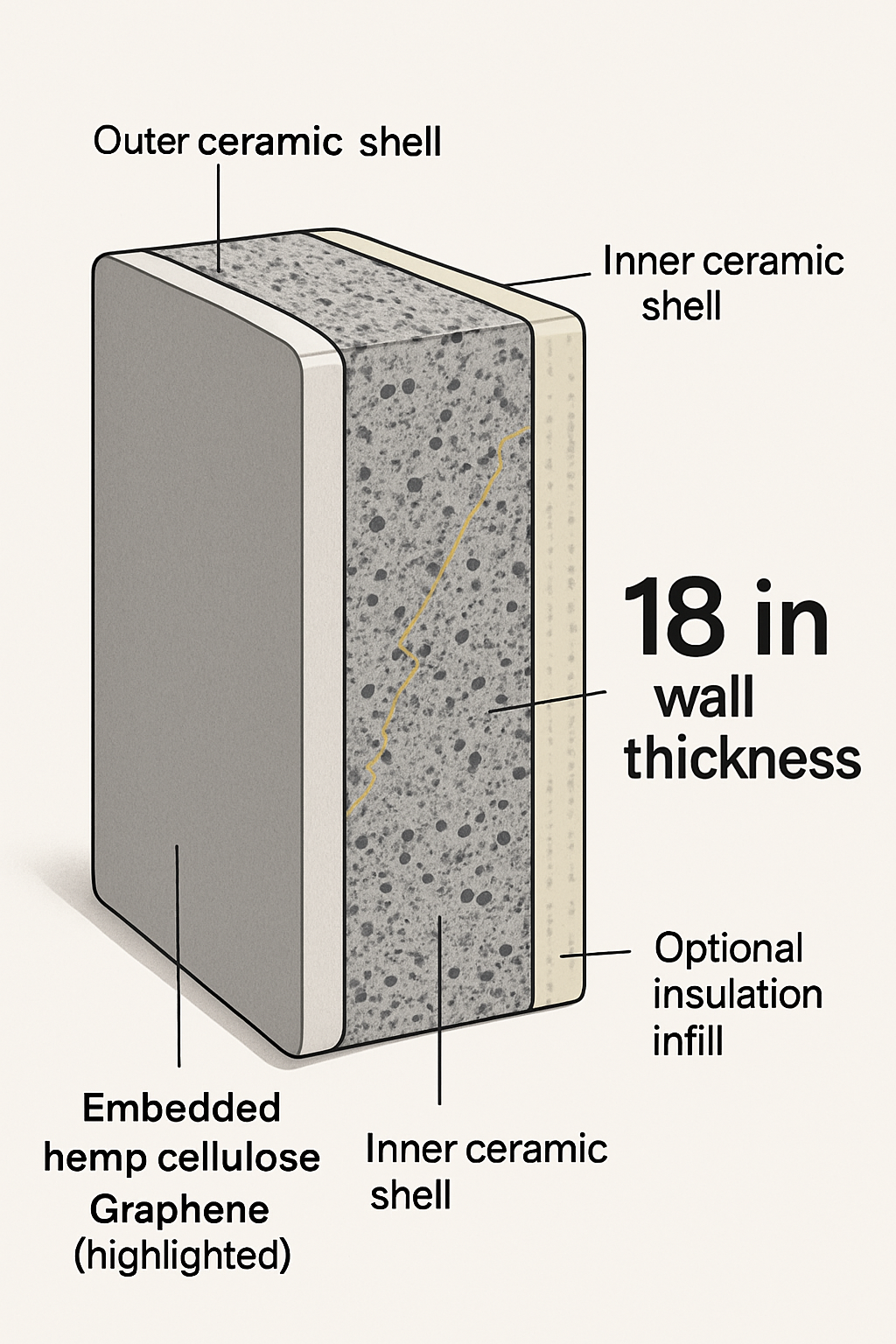

Paradomes leverage an 18-inch-thick, dual-shell, panelized wall system engineered for unmatched strength and resilience. Each panel shell is crafted from next-generation ceramic composites, further enhanced with woven fabrics & graphene for superior structural integrity. Nano and microcellulose are implemented for additional reinforcement to cellulosic foam ceramic cores that contribute to the overall insulative, compressive strengths, & environmental stability.

Our cellulose is responsibly sourced from renewable hemp or upcycled from waste streams, significantly reducing environmental impact while adding pivotal strength to the composite matrix. This pioneering approach results in walls that are not only highly fireproof and disaster-resistant, but also fundamentally sustainable.

The result: homes that withstand nature’s extremes, deliver long-lasting safety, and embody the future of eco-friendly living.

Paradome floors and roof systems are lightweight, waterproof, and pre-engineered to support all projected live loads—including high winds, most seismic events, debris impacts, and designed to easily pass the Miami-Dade County ballistic intrusion tests. Testing is underway to certify ballistic resistance to bullet penetration. This ensures exceptional structural integrity and adaptability, making our Parabolic Paradomes suitable for a wide range of uses and environments.

A key innovation that we are working to evolve now is the ability to use our parabolic shells, integral to our roof design to create the ability to mount our parabolic shells within a dual-axis tracking system, allowing the structure to follow the sun and function as a solar thermal dish. This enables Paradomes to generate superheated air to charge large thermal batteries, which can subsequently utilize Rankine cycle engines to generate electricity with the goals of seamlessly integrating renewable energy production that could supply several buildings ' needs for heat & cooling from one solar thermal dish, further advancing sustainable living.

Paradome wall cavities can be filled with high-performance cellulosic foam ceramic insulation for excellent thermal efficiency and low moment of inertia, or, for those seeking an even greater connection to traditional methods, they can optionally be filled with pneumatically impacted stabilized earth—creating a true rammed earth thermal battery infill reminiscent of classic rammed earth or earthship type autonomy homes. This flexibility empowers owners to select the most eco-friendly insulation option for their climate and needs, ensuring optimal energy efficiency and sustainable comfort.